High in a remote mountain village, where power lines vanish into the mist and storms roll in without warning, a small solar station hums quietly through three days of relentless rain. Inside a rugged metal cabinet, a set of unassuming 2V batteries pulses with steady rhythm—powering lights, radios, and medical equipment. No drama. No failure. Just silent, unwavering energy. This is not luck. This is engineering.

Meet the unsung hero of resilient solar systems: the solar 2V colloidal battery. While solar panels capture the sun’s energy, it's these robust cells that ensure your system never blinks—even when skies stay gray for days. But what makes them so much more reliable than conventional lead-acid or AGM batteries? And why are engineers increasingly turning to 2V gel technology for mission-critical installations?

The Science Behind Silent Strength

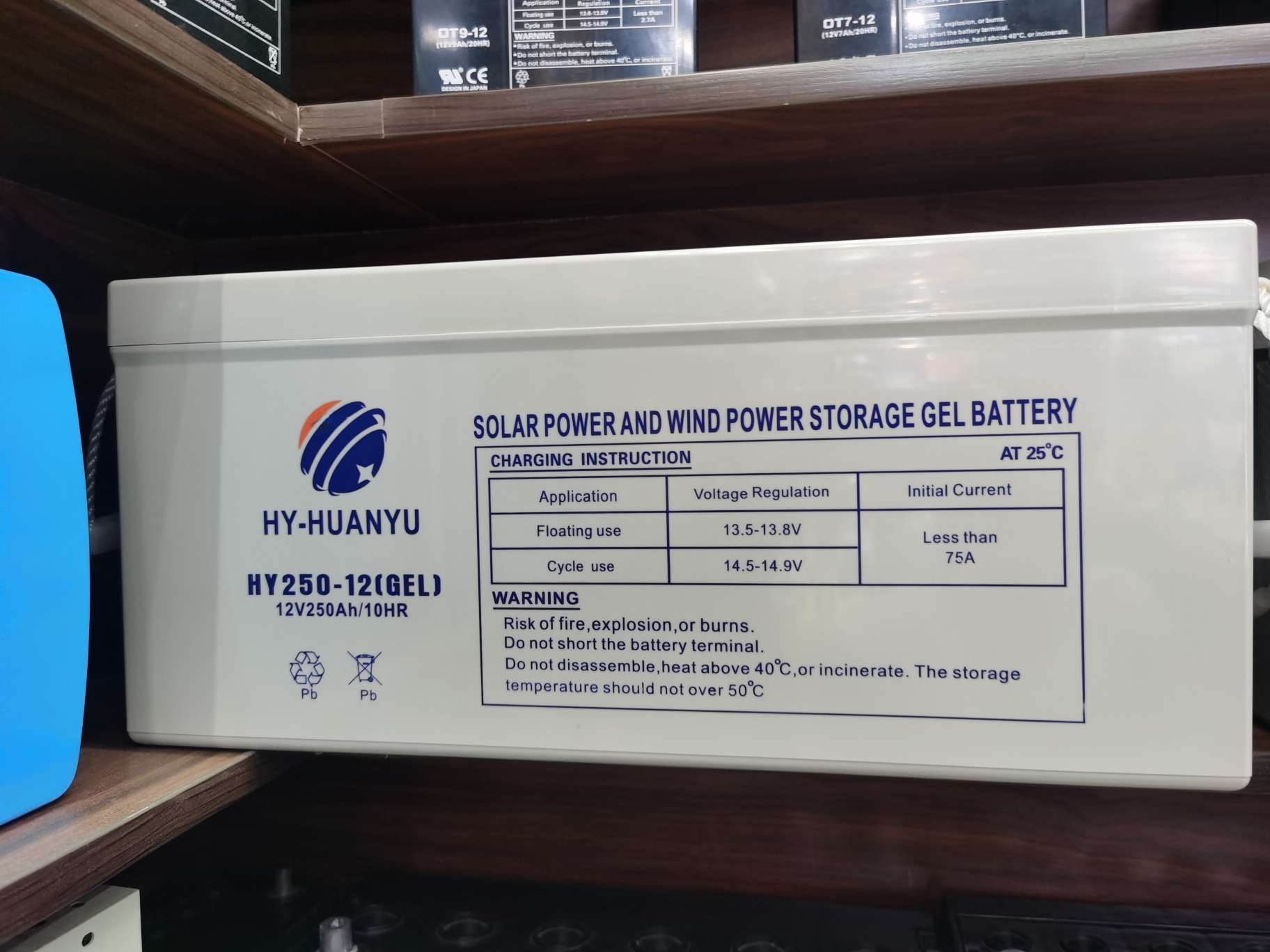

At first glance, a 2V colloidal battery looks like any other deep-cycle unit. But beneath its tough casing lies a revolutionary electrolyte design. Instead of liquid acid or absorbed glass mat (AGM), it uses a silica-based gel—a thixotropic matrix that immobilizes the electrolyte completely. This “colloid” isn’t just thicker; it’s smarter. It prevents acid stratification, reduces water loss, and resists leakage even under severe tilting or vibration.

Compared to traditional flooded lead-acid batteries, which degrade quickly under partial state-of-charge operation, or AGMs that suffer from thermal runaway in hot climates, colloidal batteries excel in deep cycling and temperature resilience. Their self-discharge rate is less than half that of standard types, meaning they retain charge longer during extended cloudy periods—critical for seasonal or backup use.

And then there’s the voltage architecture: individual 2V cells. Why go modular? Because scalability and redundancy matter. By assembling multiple 2V units into 12V, 24V, or 48V banks, system designers gain precise control over capacity, lifespan, and fault tolerance. If one cell weakens over time, it can be replaced without scrapping the entire bank—a luxury most sealed batteries don’t offer.

Forged in Extremes: Real-World Proof of Endurance

In Tibet, at an altitude exceeding 4,500 meters, a telecommunications relay station faces winter nights plunging to -30°C. Standard batteries falter in such cold—electrolytes freeze, internal resistance spikes, and cranking power vanishes. Yet here, a bank of 2V colloidal cells starts reliably every morning. How? The gel structure maintains ion mobility even in sub-zero conditions, while thick lead plates withstand repeated freezing-thawing cycles without warping.

On a humid island near the equator, salt-laden air and 95% humidity would corrode most battery terminals within months. But after five years, the same type of installation continues to run maintenance-free. No topping up. No equalization charges. Just consistent output. The sealed design and corrosion-resistant alloy grids make this possible.

Even in desert research outposts, where daytime heat exceeds 50°C and nighttime temperatures drop below freezing—creating a brutal 70°C daily swing—these batteries maintain over 85% of their rated capacity after six years. Thermal stability isn’t just a spec; it’s survival.

The Hidden Stabilizer in Your Solar Ecosystem

Modern solar systems demand more than storage—they need stability. A high-quality 2V colloidal battery acts as a dynamic anchor, smoothing voltage fluctuations and supporting inverters with low internal resistance. This means cleaner AC output, reduced stress on connected devices, and higher overall system efficiency.

Beyond performance, longevity is built into the core. Thick positive plates resist erosion over thousands of deep cycles. Special anti-stratification additives prevent acid layering. And integrated pressure-relief valves respond intelligently to gas buildup, eliminating explosion risks even in poorly ventilated enclosures.

Choosing the Right Energy Cell for Your Project

Whether you're powering a single home or a large microgrid, selecting the right configuration starts with understanding your load profile. For small off-grid homes prioritizing cycle life, a string of high-cycle-count 2V cells offers decades of service. In commercial backup scenarios, where space and response speed count, optimizing for capacity density and parallel stability becomes key. And for utility-scale solar farms, uniformity across hundreds of cells ensures balanced charging and maximized ROI.

One tip often overlooked? Charging strategy. Colloidal batteries thrive under controlled voltage profiles—typically between 2.23V and 2.35V per cell, depending on application. Overcharging dries the gel; undercharging causes sulfation. Pairing them with a smart charge controller or BMS isn’t optional—it’s essential.

Toward a Smarter, More Resilient Energy Future

The future of solar storage isn’t just about capacity—it’s about intelligence. Next-generation 2V colloidal systems are integrating with advanced Battery Management Systems (BMS) that monitor cell health, temperature, and charge history in real time. Remote diagnostics allow operators to predict failures before they happen, slashing downtime and maintenance costs.

Moreover, hybrid architectures are emerging—where colloidal batteries handle base-load stability, and lithium packs deliver peak power. Together, they create a balanced, cost-effective solution that leverages the best of both chemistries.

As climate challenges grow and energy demands rise, perhaps we’re not just upgrading our batteries—we’re redefining what “reliable power” truly means. Is your system ready?